Our Software

Accurate measurement beyond μ.

PROMESS Software

The PROMESS software will shorten your cycle time. As a result, you will avoid unnecessary manufacturing costs and simultaneously you will minimize waste, as this is reliably identified. Thus, PROMESS is user-friendly on the outside and intelligent on the inside.

Different instruments of control and regulating technology have been incorporated in the PROMESS software. They enable you to perform an individually plannable data collection, which assists you during the process monitoring and process control. An example for this is the visualization of the measuring results and the communication with the manufacturing machines.

The PROMESS software is based on many years of experience and has been developed further continuously with the aid of customer feedback. It assists you during the solving of your testing tasks and is characterized by a smooth data transmission and the recording and calculation of exact measuring data. Using the software, you can effortlessly complete both simple as well as complex measuring tasks. Furthermore, you can store measuring-related events that are called up automatically or in the event of a process violation.

The PROMESS SPC software is suitable for any measuring task. It optimizes the entire production of components and improves the waste statistics.

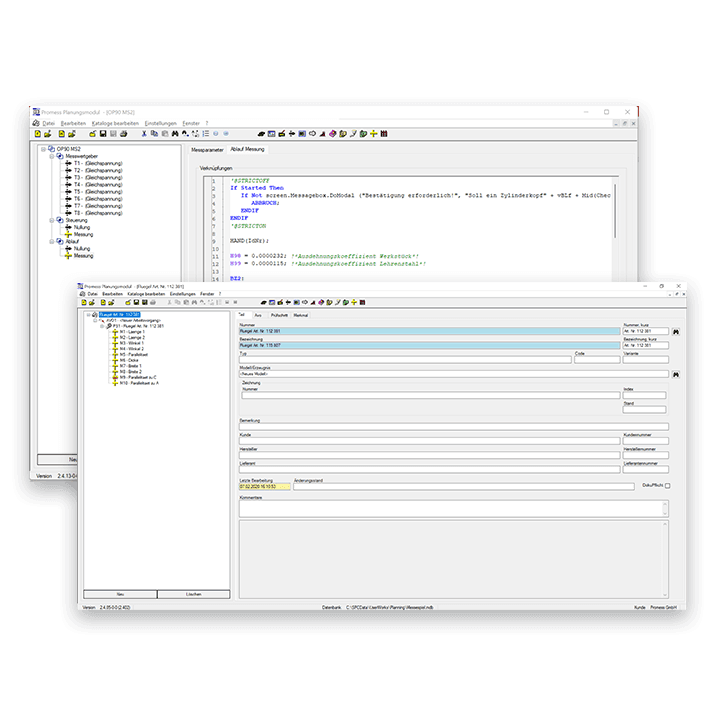

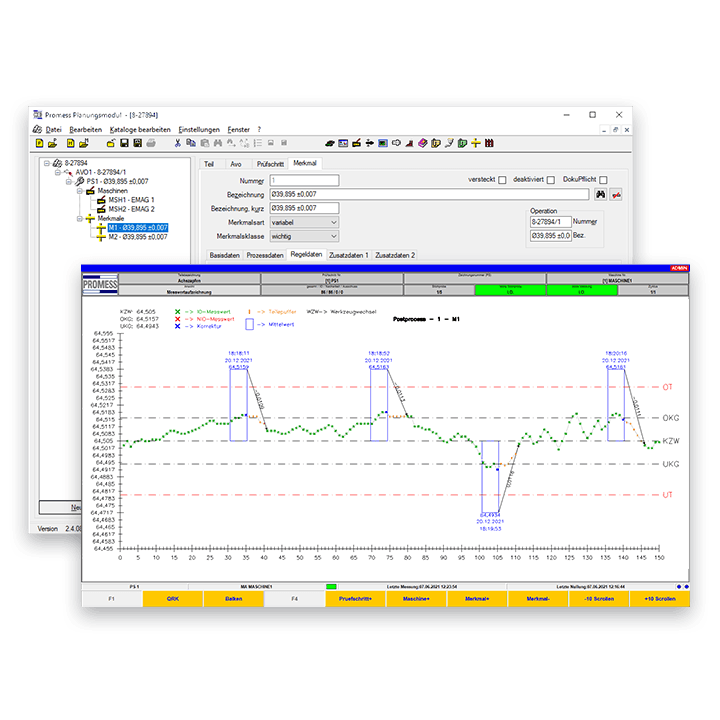

PROMESS Planning Module

Individual test plans can be prepared with the PROMESS Planning Module, which are utilized later on during the data collection.

The sub-division into work and test processes enables a clear presentation of all work sequences and measuring tasks of a component. For each single measuring task, you can define the characteristics and the sequence of their registration in a very individual manner. In addition to the input of the required parameters such as the nominal dimensions or tolerances, you can perform additional settings such as data for the statistical process monitoring or the automatic control adjustment of a machine tool.

The flexible parameter assignment enables a precise adjustment to the different company norms and customer standards.

Test instructions can also be stored on each measuring step. This ensures reliable monitoring and facilitates the intuitive operation.

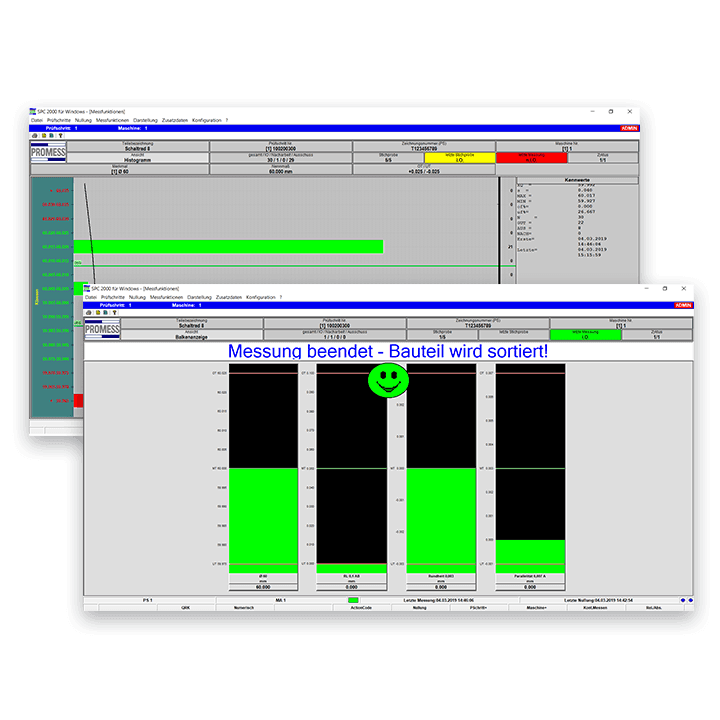

PROMESS Measurment Software

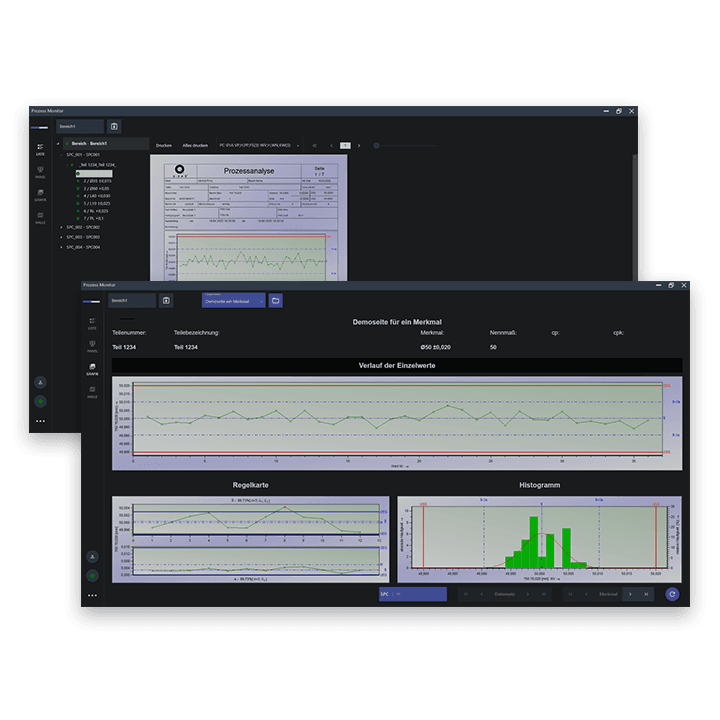

The PROMESS Measurement software captures the measured values. The collected results can be presented in different manners.

They can be output as bar charts, in a table, in control charts (with mean value and dispersion), as a histogram, normal probability plot or in an individually generated Promess parts image or a graphical display.

Each assessment makes it easier for the operator to control their manufacturing process. As soon as planned limits are exceeded, then a timely intervention in the manufacturing process is possible. This guarantees a smooth process sequence and minimizes waste. All measuring tasks can also be controlled automatically via a joint interface, for example by a PLC.

The measured values can be transmitted online to other evaluation systems. Likewise, a connection to the PROMESS Proverview, qs-STAT or a PPS system is possible.

Supplementary software modules

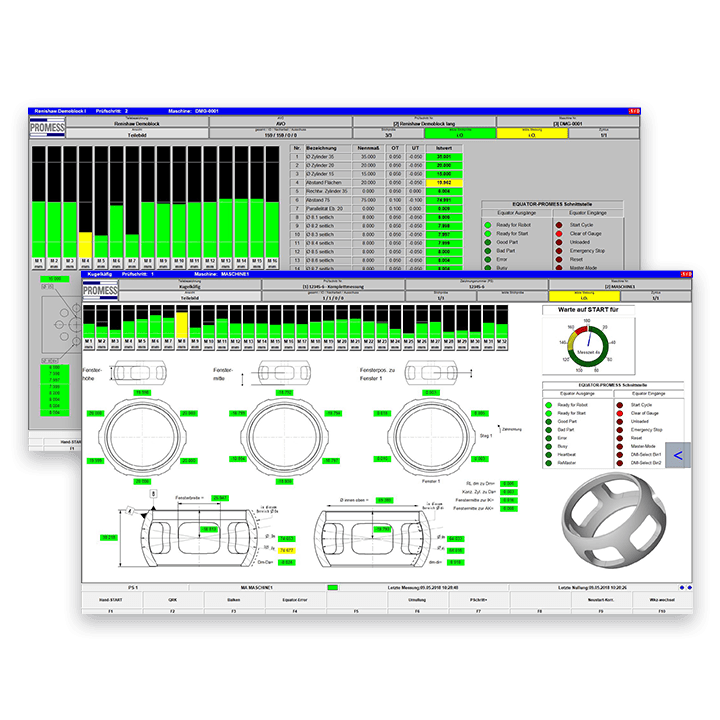

The PROMESS standard software offers different supplemental software modules. The operator can interactively ensure a fault-free measuring sequence for example with the use of graphics and instructions.

A centralization of several PROMESS measuring stations is possible with the Proverview tool. This module does not only provide a quick overview, but it also enables a comfortable monitoring of the current processes and the display of selected measuring data of several measuring stations.

We manage your process – Components can be checked to 100% in the manufacturing cycle by the measuring devices (post-process) connected to the machine. Each deviation will be determined immediately. The captured measuring deviations and completed processed correction values are transmitted with a direct connection of our measuring computers to the machine control or a higher-level PLC.

The “Teilebildeditor” (part image editor) program provides a measuring image on each measuring step. This can be output as a photograph or graphic with the desired measured values. Design your evaluation or the operator guidance exactly according to your wishes.

PROMESS Proverview

The Proverview software module evaluates the measuring data of many different manufacturing processes according to statistical parameters and presents the results on one or more display screens.

Prepare your desired overview and configure your statistical evaluations in different screen displays that can be switched. Create an overview that you can assign based on the images of the measured components in alignment with the respective statistic. Manage the test logs in a folder with a colored status display or store your hall plan. You decide whether a colored status display is sufficient or if a selected statistic should optimize your process overview and control.

Process control with PROMESS (SPR)

You decide how your machine should be corrected. With the support of numerous integrated algorithms, the Promess software can provide correction values that have been tailored exactly to your machine.

Alternatively, there is the possibility of only transmitting the determined dimensional deviations or measured values. You can then determine the required corrections with your own algorithms in your machine.

With our flexible and proven machine interface “Standard-2” you have access to all relevant functions of the measuring computer. The continuously increasing functional scope of this interface provides complete transparency on the measuring sequence for your control. This guarantees reliable and secure communication.

PROMESS Correction Map

Do you require an overview of the calculated correction values and would like to observe the effect on the ongoing process? – The new PROMESS correction chart in the measuring software version 2.2 offers precisely this.

With the correction chart you can observe the correction behavior of the individual measured values with additional information over the course of time on the implemented correction.

Benefit from the transparency of the current correction behavior directly on the measuring computer during running operation. This will save you time-consuming data analysis in external programs such as Microsoft Excel.

And what can we do for you?

We are the experts for process monitoring and quality assurance. We would be happy to also develop an individual software solution for your specific requirements. Contact us.